Description

Description

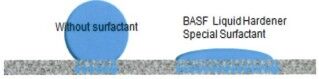

Contained wet surfactants help product penetrate the pores of concrete subtrate around 4-6 mm

With special surfactant, BASF Liquid Hardener can penetrate deep into pores and capillaries of cement matrix.

What Is a Liquid Hardener?

Liquid floor hardener formulations vary from manufacturer to maufacturer, but they usually contain inorganic compounds that under-go a series of complex chemical reactions with the available lime in mature concrete. Some liquid hardeners also contain special proprietary ingredients to make treated floors more resistant to chemical attack and wear and to improve the aesthetics of the finished surface. Unlike sovent-based, membrane forming sealers, which usually contain resins and hazardous solvents, most liquid floor hardeners contain inorganic compounds that are water soluble and comply with today’s environmental, health, and safety regulations. Wetting agents (surfactants) are usually added to a liquid hardener to help the product penetrate the prose of the concrete substrate. The efficiency of the floor hardening treatment increases with the depth of penetration, which usually ranges from 1/8 to 1/4 inch

How Do MASTERKURE® 260 Liquid Hardeners Work?

As soon as a Masterkure®

260 liquid floor hardener is applied to a concrete substrate, a chemical reaction takes place between the inorganic compounds and lime (whether hydrated or unhydrated) in the pores of the

concrete matrix. The primary product of this reaction is a mixture of dicalcium and tricalcium silicate compounds, which hydrate (react with water) even further to produce a chemical compound called calcium silicate hydrate, or tobermorite gel.

The ultimate strength and binding properties of hydrated Portland cement are primarily due to the presence of tobermorite gel in the concrete matrix. Therefore, Masterkure® 260 liquid hardener increases concrete strength by increasing the concentration of tobermorite gel. Masterkure® 260

Liquid floor hardeners can also increase concrete’s density. When the tobermorite gel forms in the concrete pores, its crystalline growth effectively blocks voids in the concrete, decreasing the pathways for moisture movement. Since chemical attack concrete by penetrating the matrix, the presence of an insoluble gel in the substrate’s pores and on its surface greatly increases the

concrete’s chemical resistance.

In addition to the benefits of strength gain and chemical resistance, a Masterkure® 260 liquid hardener can enhance the beauty of a toweled floor by giving it a polished look. This high sheen results when the treated floor is polished by mechanical means. Floors treated with Masterkure® 260 liquid hardeners will not dust when abraded or polished